Photo Illustration by Sawyer Loftus

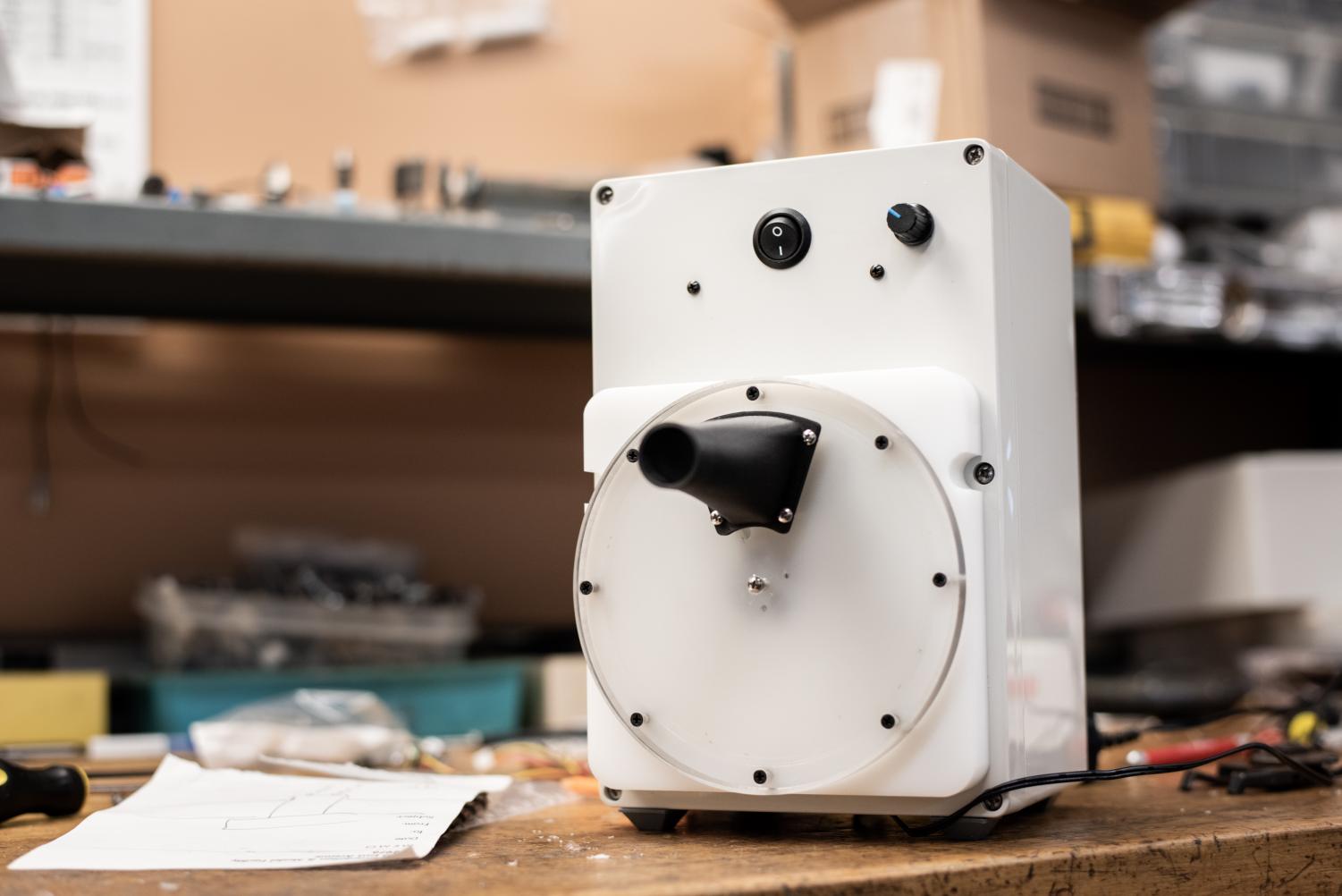

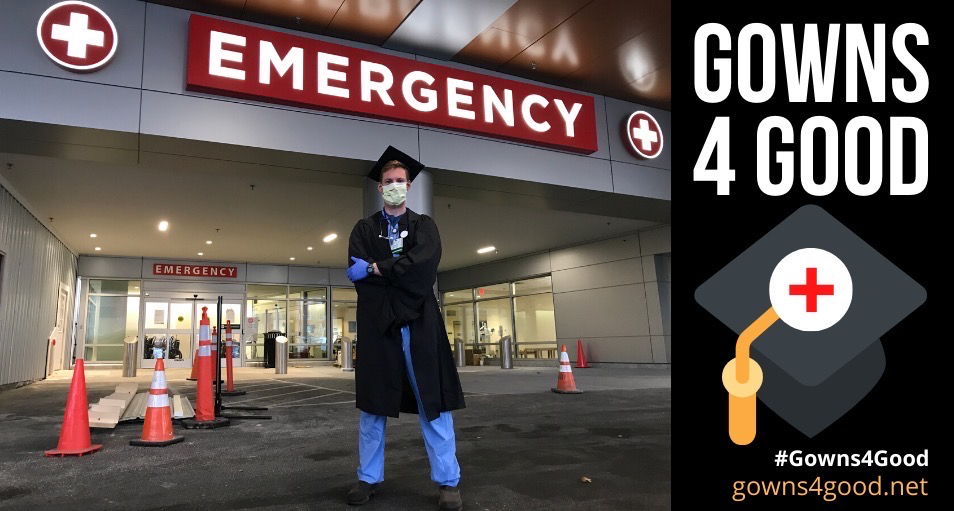

From emergency ventilators to personal protective equipment, members of the UVM community have stepped up to aid in the fight against COVID-19. Left, a portion of an emergency ventilator is made (Photo by Ian Thomas Jansen-Lonnquist). Right, Than Moore stand in front of the UVMMC Emergency Room (Photo by Taran Catania SI-MBA’20).

UVM community innovates to save lives in fight against COVID-19

April 16, 2020

Despite bleak circumstances, many UVM community members have stepped up to face the COVID-19 crisis head-on.

From creating life-saving devices for coronavirus patients to protecting medical professionals in the workplace and helping students with mental health struggles, the UVM community is working quickly and tirelessly to respond to this pandemic and many of its complications.

The Vermontilator

The “Vermontilator,” is meant to be a supplement to a foreseen shortage of life saving medical equipment in Vermont, in the fight against COVID-19.

To supplement a foreseen shortage of life-saving medical equipment in Vermont, a UVM professor, along with some colleagues, are racing against the clock to develop emergency ventilators.

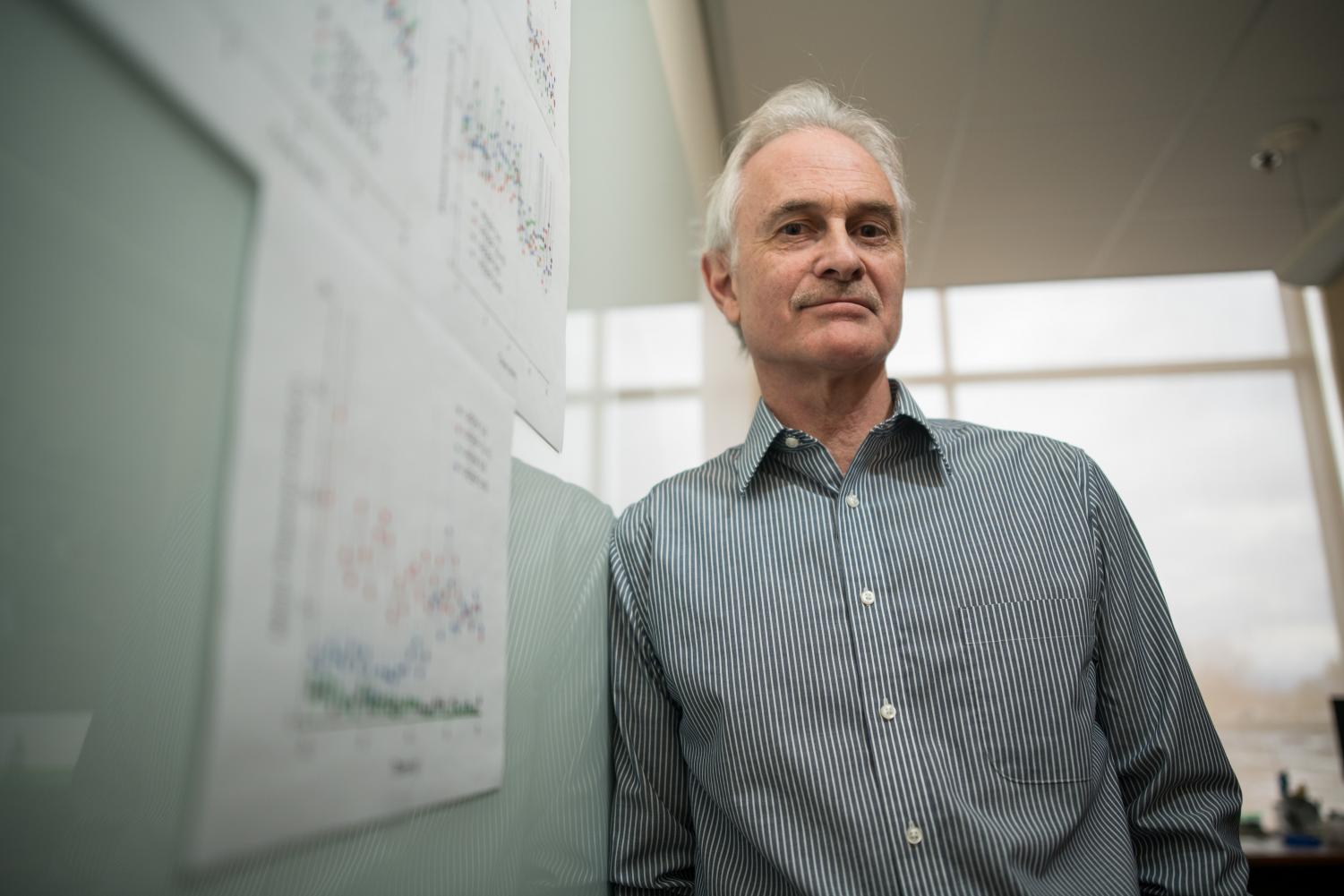

Jason Bates is a professor of molecular physiology and biophysics at UVM, and he’s been working on a device he and his team call the Vermontilator.

“It’s close to its final prototype stage,” Bates said. “By that, I mean days away from submitting an emergency authorization use application to the FDA.”

About a month ago, Bates was coming up with ideas to create a mechanical ventilator.

“I am not a medical doctor, I’m a biomedical engineer physiologist,” he said. “But I know a great deal about this stuff because I’m an expert in lung physiology, and I’ve been doing research on it for more than 30 years.”

Bates found that traditional mechanical ventilators often allow the lungs to collapse so much between inflations, that already delicate and inflamed lung tissue sticks to itself and can peel, causing damage that can be just as fatal as not being on a ventilator at all, he said.

“The ventilator can become a double-edged sword, is a good way to put it,” Bates said.

Bates noticed a patient at the UVM Medical Center on a kind of ventilation called Airway Pressure Release Ventilation about a month ago.

He has been studying APRV and has found that it has the potential to be far more gentle on injured lung tissue.

On March 16, UVM research engineer Jake Kittel sent Bates a text asking if he would be interested in collaborating on an emergency ventilator.

Bates had already drawn up several diagrams for a simple APRV ventilator just a few days prior.

Jason Bates is a professor of molecular physiology and biophysics at UVM. He along with a team of colleagues created what they call the “Vermontilator.”

Bates sent Kittel his ideas and they quickly involved two other UVM engineers and the director of UVM’s Instrumentation Modeling Facility to collaborate.

Within only 24 hours of their first correspondence, the engineers had assembled a prototype.

“We started meeting by Zoom every morning, and we’ve done so ever since, right through the weekends,” Bates said. “Everybody’s been working like hell.”

The UVM Office of Technology Transfer is currently helping them to secure a patent, he said.

“Things moved ahead rapidly and I suddenly found that I was devoting pretty much all my time to this,” Bates said. “I got interviewed by local channels of ABC, CBS and NBC and the New Yorker magazine, I mean, this is a surreal experience for me.”

People throughout the UVM community and Vermont have gotten involved, including people from the state governor’s office and Sen. Patrick Leahy’s office.

“Luckily, anyway, we’ve had tremendous interest and support,” Bates said. “We’ve had emails from people all over the place, particularly Vermont, offering their help.”

He hopes to have a proposal for emergency approval into the Food and Drug Administration office within days.

“What we’re doing is we’re gearing up to be ready for a situation when they might be needed and we have to realize, of course, that doesn’t guarantee they will be used,” Bates said. “But we have to put in all the effort necessary to get to the point where they could be.”

As of right now, there are no numbers set in stone, but Bates said they are looking to make roughly 20 Vermontilators onsight and 500 with manufacturers, to be distributed across Vermont wherever they are needed.

There is also the possibility for these ventilators to be produced in other parts of the country and world if they are needed, Bates said, once they have been given FDA approval and things are at a stage where those considerations can be made.

Once the pandemic is over, any FDA emergency approvals will become nullified, because they will no longer be needed here, Bates said.

“But when the dust settles on COVID-19, who knows? Maybe we have something that could become useful in the developing world, or maybe with a few tweaks, assume some other sort of use, I don’t know,” he said. “But this experience has brought the UVM community together and made us realize just what we are capable of.”

Gowns4Good

Than Moore, is a physician’s assistant at UVM Medical Center and student in the Sustainable Innovation MBA program at UVM. Recently, he started a program to recycle graduation gowns as personal protective equipment for healthcare workers.

Than Moore, a physician’s assistant at UVM Medical Center and student in the Sustainable Innovation MBA program, just started a project in which students can donate their graduation gowns to health care workers to be used as Personal Protective Equipment.

Within two days of coming up with the idea, the project known as Gowns4Good had a team together, a website up and was fully operational, Moore said.

“It just kind of took off from there,” Moore said. “Every day we’ve been receiving hundreds of donors. We’ve received thousands of requests from medical facilities as well, the numbers keep escalating.”

The website is organized with donation and request tabs, and anyone who fills out a donation form will receive an email with cleaning and mailing instructions.

Than Moore, is a physician’s assistant at UVM Medical Center and student in the Sustainable Innovation MBA program at UVM. Recently, he started a program to recycle graduation gowns as personal protective equipment for healthcare workers.

The gowns are then collected and double-checked for cleanliness and then shipped in bulk to medical facilities, Moore said.

For schools that have postponed their graduations or are doing a digital ceremony rather than canceling it altogether, Moore still hopes that many of those students will be willing to donate their gowns.

Moore, who is set to graduate next month from UVM, said his own experience drove his idea.

With his graduation ceremony canceled, he learned about so many other healthcare workers who were practicing without proper PPE and knew there was a way to reconcile both scenarios.

“In the back of my mind, I’ve been thinking about what more can I offer?” he said.